1.2083esr

Title: 1.2083 ESR The Ultimate Molding Steel for Precision

Steel is the backbone of modern industry, and precision engineering demands exceptional materials that can stand up to the most challenging applications. Among these materials, 1.2083 ESR stands out as a premium choice for its exceptional balance of hardness, ductility, and wear resistance. As a mold steel engineer at Dongqi Special Steel, I'm excited to delve into the details of this remarkable alloy and explore its applications in the world of precision tooling.

1.2083 ESR (also known by its other designations, like AISI H13 or DIN X 40CrMoV51) is a highquality, lowalloy tool steel that's been engineered to provide excellent performance in demanding environments. The "ESR" in its name refers to the ElectroSlag Remelting process, a stateoftheart technique used to refine and purify the steel, resulting in a material with fewer inclusions and superior physical properties.

At the core of 1.2083 ESR's appeal is its ability to achieve high levels of hardness without sacrificing toughness or ductility. This is crucial for applications that require both strength and the ability to absorb impact without cracking. The steel's alloy composition, which includes elements like chromium, molybdenum, and vanadium, gives it these characteristics while also providing excellent heat resistance and resistance to thermal fatigue, making it ideal for applications involving high temperatures.

One of the most significant advantages of 1.2083 ESR is its ability to maintain its performance over time, even in the most demanding conditions. The alloy's high resistance to wear and corrosion means that it can withstand the rigors of continuous use without significant degradation, making it a costeffective choice for industries where downtime and replacement costs can be significant.

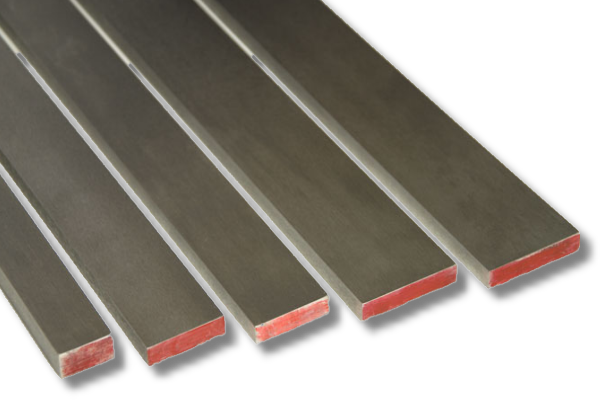

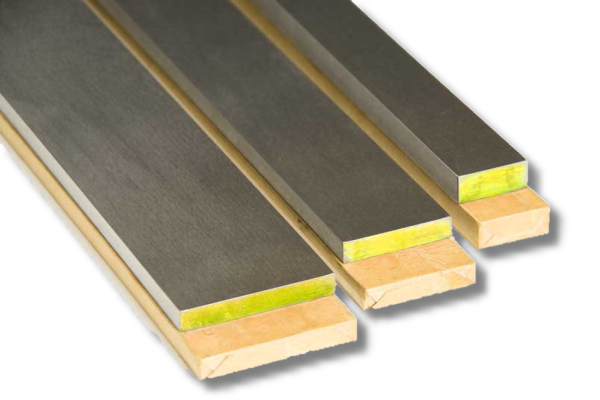

In terms of applications, 1.2083 ESR is a versatile alloy that's found a home in a wide range of industries. It's commonly used in the manufacturing of injection molds for plastics, diecasting molds for metals, and other precision tools where high levels of wear resistance and dimensional stability are critical. Its ability to withstand high temperatures and resist thermal shock also makes it an excellent choice for applications in the automotive and aerospace industries, where parts are often subjected to extreme heat and stress.

The ESR process used in the production of 1.2083 ESR is a key factor in its superior performance. This advanced technique involves melting the steel multiple times, which helps to refine its microstructure and eliminate impurities. The result is a material with exceptional homogeneity and consistency, which translates to improved performance and reliability in realworld applications.

In conclusion, 1.2083 ESR is a highperformance alloy that's wellsuited to a wide range of precision tooling applications. Its combination of hardness, toughness, and wear resistance, coupled with its ability to maintain these properties over time, make it a top choice for engineers and manufacturers seeking a reliable and costeffective solution. At Dongqi Special Steel, we're proud to offer this exceptional material to our customers, and we're committed to continuing our research and development efforts to bring even more advanced materials to the market in the future.

This article is an exploration of the many benefits of 1.2083 ESR, a premium alloy that's setting new standards in the world of precision tooling. As a mold steel engineer, I'm excited about the possibilities that this material offers and the role it can play in driving innovation and efficiency in a wide range of industries.

人工客服

人工客服 报价电话

报价电话