m390多少hrc

Title: M390 Steel: Understanding Its Hardness in HRC

Introduction:

M390 steel is a highly soughtafter material in the world of tooling, manufacturing, and knife making due to its exceptional hardness, corrosion resistance, and wear resistance. Those who work with this material often wonder about its hardness level, specifically in terms of HRC (Rockwell Hardness C scale). In this article, we will explore the hardness of M390 steel, its applications, and how it can benefit your projects.

Body:

1. What is M390 Steel?

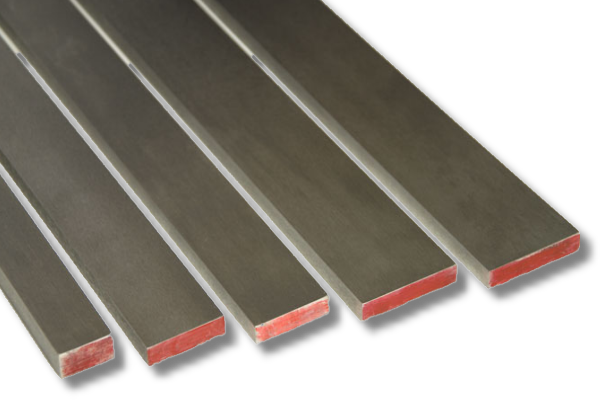

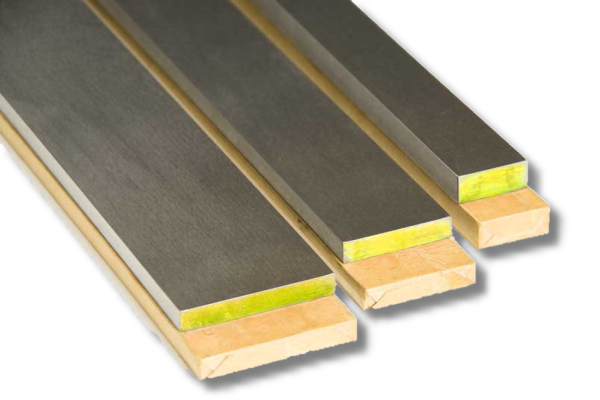

M390 is a highalloy airmelted steel known for its excellent combination of edge retention, corrosion resistance, and toughness. It is composed of elements such as Chromium, Molybdenum, Vanadium, and a small percentage of Cobalt, which contribute to its outstanding properties.

2. Hardness of M390 Steel in HRC

The hardness of M390 steel is typically measured on the Rockwell Hardness C scale (HRC), a widely accepted standard for evaluating the hardness of various materials. M390 steel generally achieves hardness levels between 6062 HRC when properly heattreated. This high level of hardness provides a longlasting edge and resistance to wear, making it an ideal choice for applications where durability is crucial.

3. Applications of M390 Steel

Due to its exceptional properties, M390 steel is widely used in various industries, such as:

a. Knives and Cutting Tools: Its high hardness and edge retention make it an excellent choice for manufacturing highquality knives, including hunting knives, tactical knives, and pocket knives.

b. Wear Parts: M390 steel is ideal for parts that experience heavy wear or abrasion, such as gears, bearings, and bushings.

c. HighPerformance : The material's hardness and resistance to chipping make it suitable for creating tools that require precision and durability, like drills, milling cutters, and taps.

4. Heat Treatment and Hardness Optimization

Achieving the desired hardness level in M390 steel requires proper heat treatment, which includes quenching and tempering processes. The heat treatment process can be finetuned to achieve the optimal balance between hardness, toughness, and ductility, ensuring the best performance for specific applications.

Conclusion:

M390 steel is a versatile and highperformance material that offers a unique combination of hardness, corrosion resistance, and wear resistance. With a typical hardness level of 6062 HRC, it is an excellent choice for applications that demand durability and precision. Understanding the properties and applications of M390 steel can help you make informed decisions when selecting materials for your projects.

人工客服

人工客服 报价电话

报价电话