2024.05.09

m390钢材的硬度

Title: M390 Steel: Unraveling the Hardness Characteristics for Precision Molding

Introduction:

In the realm of precision molding and tooling, selecting the right material is paramount to achieving desired performance and durability. M390 steel has emerged as a frontrunner in this industry, thanks to its exceptional hardness and wear resistance. This article delves into the hardness characteristics of M390 steel, exploring its benefits and applications in the manufacturing sector.

The Hardness Spectrum of M390 Steel:

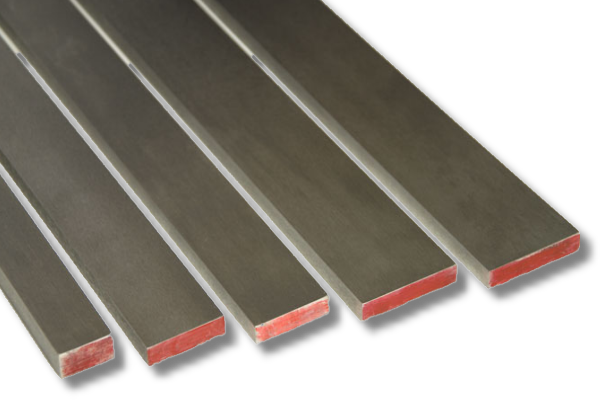

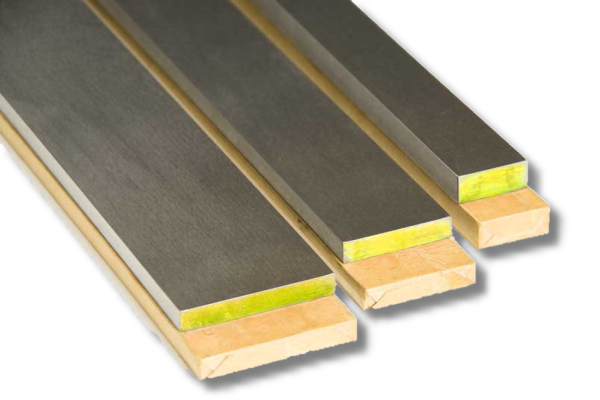

M390 steel, a highend stainless steel, boasts a remarkable hardness level that ranges from 58 to 62 HRC (Rockwell C scale). This hardness, coupled with superior toughness, makes M390 an ideal choice for applications involving high wear, such as dies, molds, and cutting tools.

Factors Influencing M390 Steel Hardness:

The hardness of M390 steel is influenced by various factors, including its chemical composition, heat treatment process, and manufacturing techniques. M390 steel's chromium, molybdenum, and vanadium content significantly contribute to its hardness and corrosion resistance. The steel's hardness can be further enhanced through precise heat treatment and quenching processes.

Applications of M390 Steel:

Given its hardness and wear resistance, M390 steel is widely utilized in the manufacturing of cutting tools, dies, and molds for plastic injection, extrusion, and blow molding. It is particularly favored for applications requiring intricate details and longterm durability.

Advantages of M390 Steel:

The high hardness of M390 steel offers several advantages, including:

1. Enhanced Wear Resistance: M390 steel's hardness makes it highly resistant to abrasive wear, prolonging tool and mold life.

2. Improved Dimensional Stability: The steel's hardness contributes to its excellent dimensional stability, ensuring consistent and precise molding results.

3. Superior Corrosion Resistance: M390 steel's alloy composition provides excellent corrosion resistance, making it suitable for molds and tools exposed to corrosive environments.

Conclusion:

M390 steel's impressive hardness, combined with its wear resistance and corrosion properties, positions it as a premium material for precision molding and tooling applications. By understanding the factors influencing its hardness and leveraging its advantages, manufacturers can optimize their processes for superior results. As the demand for highprecision components continues to rise, M390 steel will undoubtedly remain a cornerstone in the mold and tooling industry.

人工客服

人工客服 报价电话

报价电话